SAIT ABRASIVI

TECHNOLOGY

SAIT ABRASIVI S.P.A.: A GROUP WITH SOLID ROOTS LOOKING TOWARDS THE FUTURE.

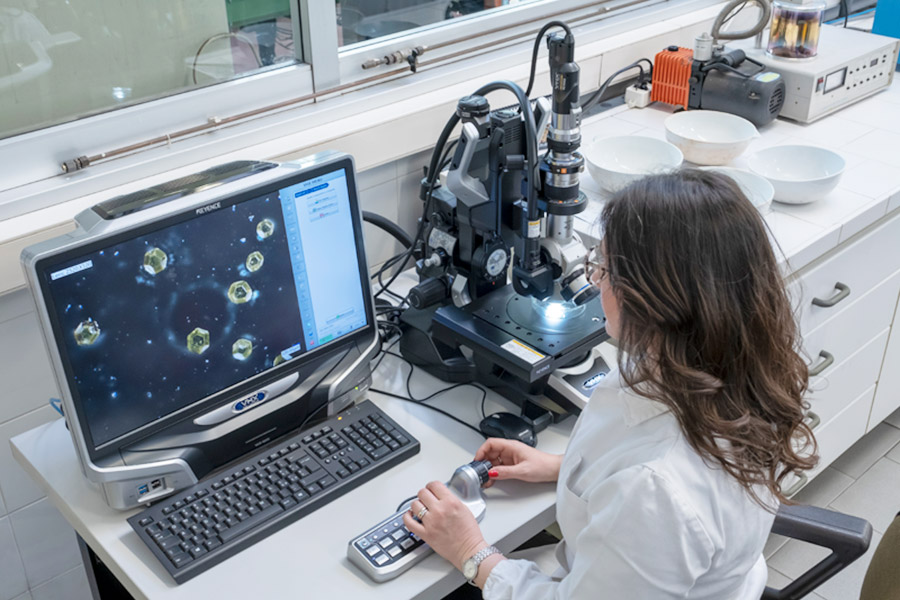

Research and development are always at the forefront of our minds, underpinned with the most advanced technologies and quality control systems allows SAIT to achieve a leading position in the world market of abrasive products.

SAIT constantly invests to maintain its plants and laboratories at the highest levels of technology and automation, to ensure Customers always receive excellence in terms of safety, quality, performance and reliability.

SUCCESS PRODUCTS

SAITDISC-D 3A

Vulcanised fibre abrasive disc capable of withstanding the heaviest machining with high contact pressures.

3A combines a high quality abrasive, such as semi-brittle corundum, with a closed structure to achieve high removal rates and a high quality finish. Semi-brittle corundum is a particularly sharp abrasive with a self-sharpening effect, which guarantees high, precise and consistent polishing performance.

The special formulation of its binder enables low-heat machining with no burning and limited clogging.

The characteristics of 3A readily respond to the special requirements of stainless steel by integrating into the surface preparation and finishing cycles needed for this material.

It is also ideal for post-welding processes, where excess weld seam is to be removed without excessively damaging the surrounding areas. A safe and reliable product with a long service life, which fits perfectly into our proposal for contexts such as the shipbuilding and food industries.

POWER MAX CUTTING WHEELS

New POWER MAX line developed to guarantee maximum performance.

The high percentage of excellent quality zirconia contained in the new POWER MAX wheels allows excellent cutting capacity and guarantees performance extremely high, making POWER MAX wheels unbeatable.

All abrasive wheels, including POWER MAX wheels, are subjected to strict and rigorous quality controls, which guarantee a high standard, both in terms of reliability and product safety. SAIT production complies with the EN 12413 standard.

POWER MAX wheels achieve maximum performance when used with high performance grinders and guarantee a fast and clean cut on steels and stainless steels.